PMEC India 2025

25th to 27th Nov 2025

India Expo Centre, Greater Noida, Delhi NCR

Stand : 9.B13

Pratham Technologies invites you to PMEC 2025. We are set to showcase our latest End-of-Line Pharma Packaging and Robotic Automation Solutions, designed to transform the way pharmaceutical products are packed, handled, and dispatched.

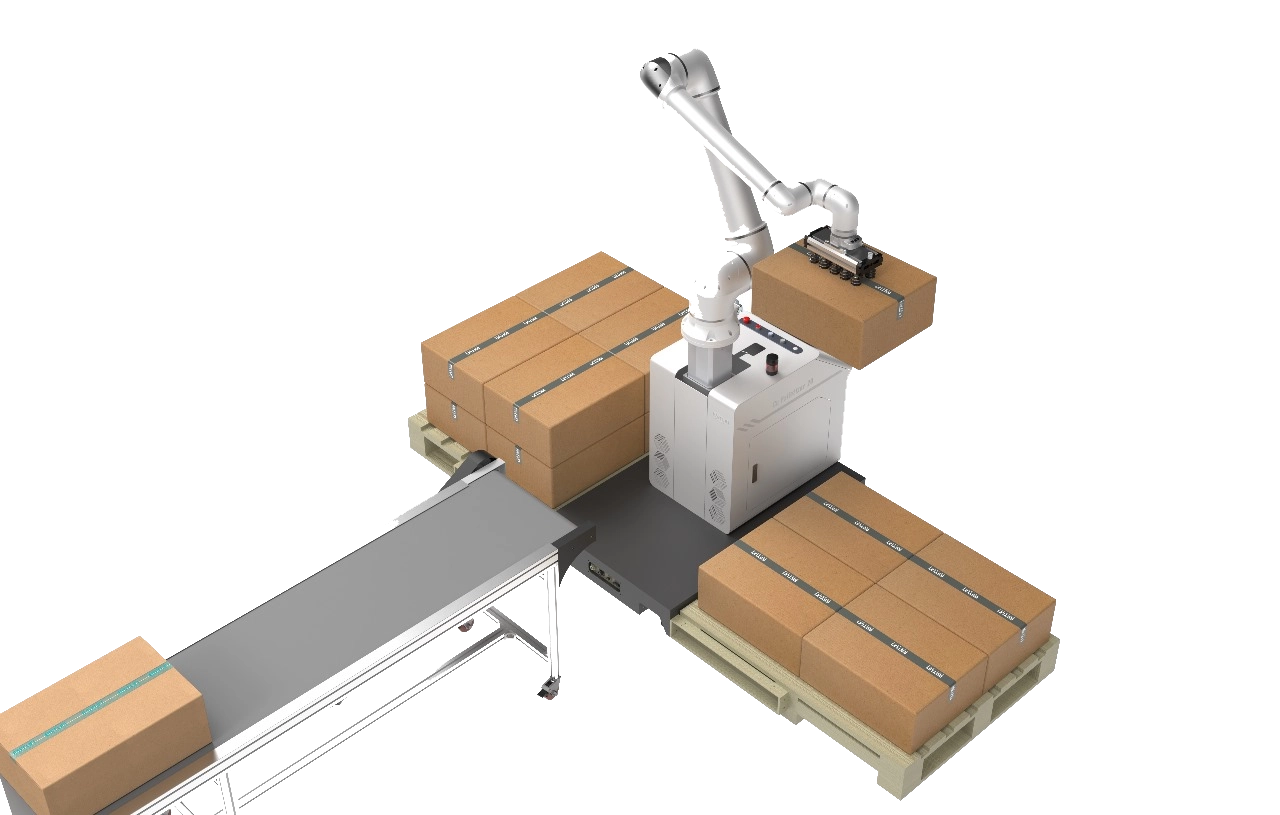

Solutions for Collaborative Robot Palletizing – enabling safe, space-efficient, and high-speed palletizing operations.

Integrated End-of-Line Automation Systems – delivering seamless coordination from carton to pallet.

Customized Robotic Applications – tailored to meet your unique production and packaging requirements.

Our automation solutions are engineered for precision, reliability, and scalability, helping manufacturers enhance efficiency, minimize errors, and achieve higher throughput.

Discover. Experience. Automate.

Meet our experts, discuss your packaging challenges, and explore tailored automation solutions for your plant.

Join us at PMEC 2025

Register Now to experience the next era of end-of-line automation with Pratham Technologies.

Contact

Sanket Selmokar- 9156476603

Email: sanket.selmokar@prathamtech.com

Join Pratham Technologies at PMEC 2025

We’re excited to invite you to PMEC 2025, where Pratham Technologies will showcase its End-of-Line Packing and Robotic Automation Solutions designed specifically for the pharmaceutical industry.

Our automation systems are built to optimize efficiency, ensure precision, and simplify complex packaging processes — helping pharma manufacturers achieve higher productivity and reliability.

Whether you’re exploring end-of-line packing, robotic automation, or looking for customized solutions for your production floor, our team will be there to understand your needs and offer solutions that fit your goals.

To Explore advanced End-of-Line and Robotic Automation built for pharma production

The ESTUN CoDroid CO-PALLETIZER 20 delivers fast, flexible, and plug-and-play palletizing automation. Setup in just 30 minutes—no coding needed. Its intuitive interface supports multiple box sizes, ensures stable stacking, and easily shifts between lines. Smart, mobile, and efficient—built for productivity with minimal integration time.